R&D support

- Electronics & material

- Construction analysis

- Reliability analysis

- Test strategy

- Thermomechanical simulation

- Thermomechanical characterization

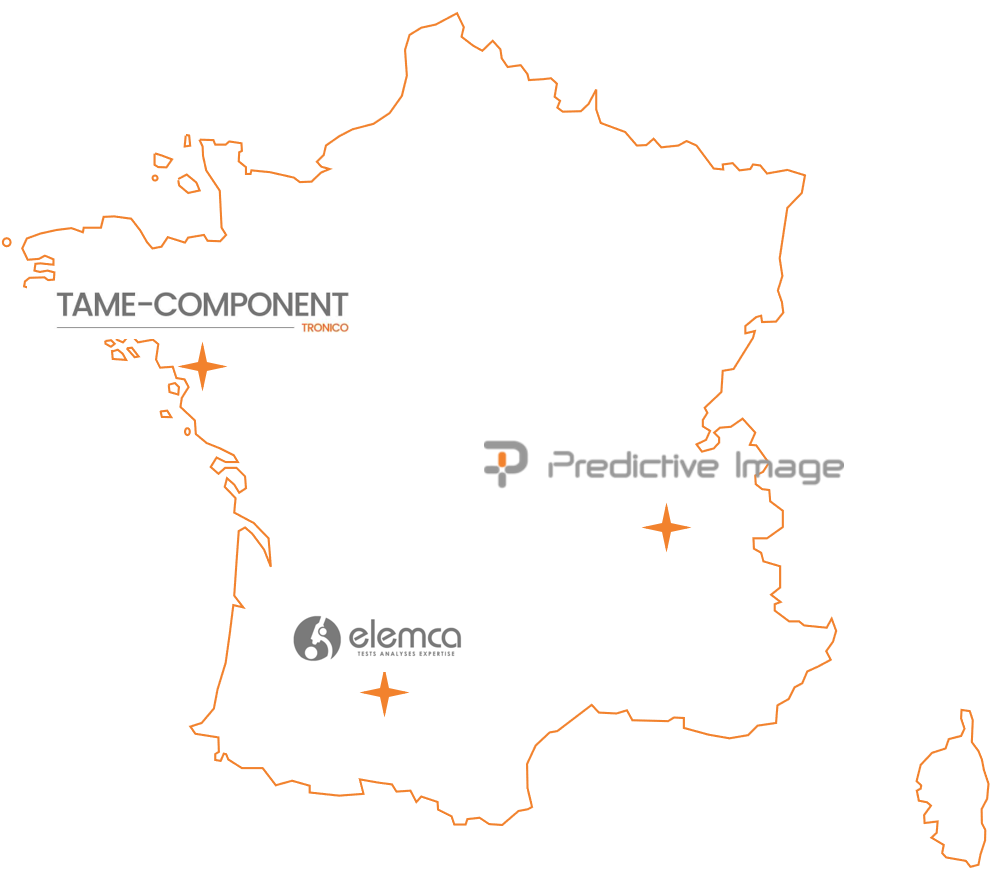

In January 2021, Tame-Component, Elemca and Predictive Image joined in a private partnership called PartLab to combine their know-how and expertise.

While preserving the total independence of each laboratory, this partnership aims to bring together the expertise and skills specific to each one in order to provide an extended technical offer with optimized costs and delivery delays.

Predictive Image remains your single technical contact, and proposes a global offer : we manage the expertises, from components to assembled PCBs. In full transparency, you will be aware of each of the services provided by our partners Elemca and Tame-Component.

By trusting PartLab, you can rest assured that your quality requirements will be maintained at their highest level. Each of the three laboratories meets the expectations of international standards.